PSC series is a flat plate sedimentation type manual unloading, intermittent operation centrifuge. This series of centrifuges has a simple structure, reliable performance, convenient operation and maintenance, the filtration time can be controlled at will, the filter residue is fully washed, the solid phase particles are not destroyed, the unloading is fast and labor-saving, and it has a wide range of uses. It is often used in chemical, food, light industry, papermaking, mining, environmental protection and other departments.

PSC series is a flat plate sedimentation type manual unloading, intermittent operation centrifuge. This series of centrifuges has a simple structure, reliable performance, convenient operation and maintenance, the filtration time can be controlled at will, the filter residue is fully washed, the solid phase particles are not destroyed, the unloading is fast and labor-saving, and it has a wide range of uses. It is often used in chemical, food, light industry, papermaking, mining, environmental protection and other departments.

The centrifuge starts loading before starting, and can also be loaded at medium or high speed. The centrifuge drum rotates at high speed. Under the action of the centrifugal field, the particles or liquids with higher density are deposited on the side close to the drum wall (outer layer), and the particles or liquids with lower density (usually liquids) are deposited on the side close to the drum interception port (inner layer). Due to continuous feeding, the liquid phase with lower density in the inner layer overflows from the drum interception port, and is discharged from the liquid outlet pipe through the channel between the outer shell and the liquid collecting tank, or siphoned to the outside of the machine by a skimming device. When the sediment (solid phase) in the drum reaches the specified requirements, stop loading, turn off the power, brake, and unload the filter cake from the drum to complete a working cycle.

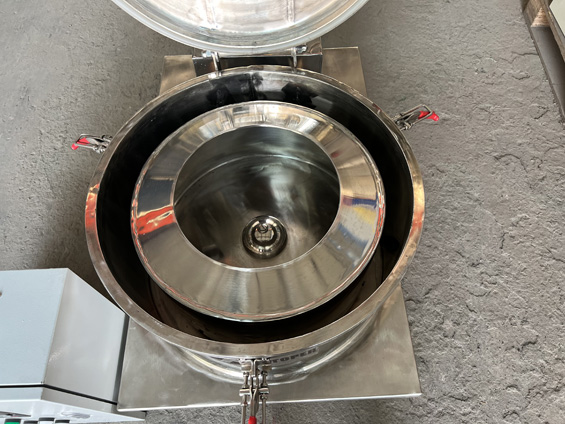

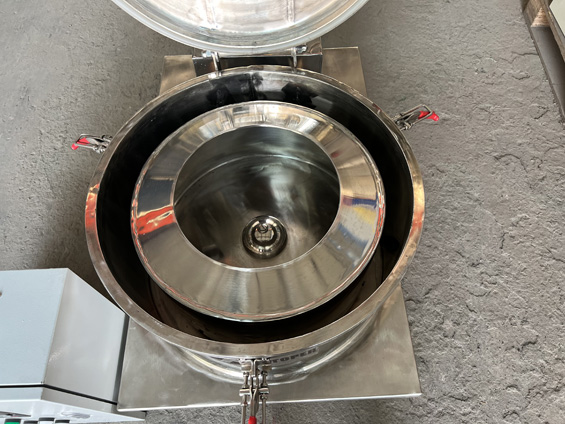

This series of centrifuges is mainly composed of a flat base, a casing, a sedimentation drum, a main shaft drive assembly, a brake device, a motor and a skimming device.

1. Structure: The flat plate and the parts that are in direct contact with the material are made of SUS304 stainless steel or 316 stainless steel.

2. Energy-consuming braking, non-contact braking method, no friction powder pollution.

3. The shock absorption and isolation system are scientifically and reasonably designed, without foundation installation, and adopts high-precision hydraulic damping shock absorbers. The vibration of the equipment is absorbed by the isolation system, which effectively reduces the vibration interference to the foundation ground and the surrounding environment.

Suitable for separation of suspensions containing medium-fine granular or fibrous materials with high viscosity, strong hydrophilicity and difficult separation; also suitable for separation of paste-like and solid materials; and widely used in dehydration of textiles and food.

Sedimentation centrifuges are commonly used in industries such as chemical, food, light industry, papermaking, mining, and environmental protection.

1. Optional frequency conversion speed regulation, smooth start-up, adjustable separation factor.

2.Frequency conversion control box safety protection: current protection, motor overload and overheating protection.

| Type | Drum | Separation factor(ω2r/g) | Power(kw) | Weight(kg) | Dimension(L x W x H) (mm) | |||

| Dimater (mm) | Volume (L) | Load limit | Rotation speed(r/min) | |||||

| (kg) | ||||||||

| PSC300 | 300 | 5 | 10 | 1600 | 1000 | 1.1 | 94 | 650×460×500 |

| PSC450 | 450 | 20 | 25 | 1600 | 990 | 1.5 | 180 | 1100×670×520 |

| PSC600 | 600 | 45 | 50 | 1500 | 756 | 3 | 700 | 1300×880×900 |

| PSC800 | 800 | 100 | 135 | 1200 | 1000 | 5.5 | 1400 | 1800×1200×1000 |

| PSC1000 | 1000 | 175 | 200 | 1000 | 675 | 7.5 | 1950 | 2000×1500×1280 |

| PSC1250 | 1250 | 350 | 300 | 960 | 645 | 18.5 | 2800 | 2200×1700×1350 |