Filter paper is a semi-permeable paper barrier placed perpendicular to a liquid or gas flow. It is used to separate fine solid particles from liquids or gases. The raw materials are usually different pulps. The pulp may come from softwood, hardwood, fiber crops or mineral fibers. Filter papers have a variety of properties, important parameters include wet strength, porosity, particle retention, volumetric flow rate, compatibility, efficiency and capacity.

Filter paper is a semi-permeable paper barrier placed perpendicular to a liquid or gas flow. It is used to separate fine solid particles from liquids or gases. The raw materials are usually different pulps. The pulp may come from softwood, hardwood, fiber crops or mineral fibers.

Filter papers have a variety of properties, important parameters include wet strength, porosity, particle retention, volumetric flow rate, compatibility, efficiency and capacity.

There are two mechanisms for filter paper filtration: volume and surface. In volume filtration, particles are captured by the majority of the filter paper. In surface filtration, particles are captured by the surface of the filter paper.

The main points to consider when choosing filter paper are:

1. Large effective area, that is, large use area of filter paper, large dust holding capacity, small resistance, long service life, and of course, the cost will increase accordingly.

2. The finer the fiber diameter, the better the interception effect, and the higher the filtration efficiency.

3. The binder content in the filter material. The higher the binder content, the higher the tensile strength of the paper, the higher the filtration efficiency, the less hair loss, the smaller the dust accumulation of the filter material, the better the resistance, but the resistance increases accordingly.

The technical indicators of filter paper can be divided into two aspects, one is the filtering characteristics of filter paper, and the other is physical characteristics. Filter characteristics include air permeability, air resistance, maximum pore size, and average pore size.

Physical characteristics include quantitative, thickness, stiffness, corrugation depth, burst resistance, resin content, etc.

Coffee and Tea Paper: Modern coffee filter paper is made of about 100 g/m2 of crumpled paper. The crumpled paper allows the coffee to flow freely between the filter and the filter funnel. Coffee filter paper comes in different shapes and sizes to fit different containers. Tea bags are also a kind of paper filter. They are made of jatropha fiber, and a small amount of synthetic fiber is usually added to the paper. Bag paper is porous and thin, with high wet strength.

Fuel Filter Paper: The paper used for fuel filters is a crumpled paper with controlled porosity that can be pleated and rolled into a filter element.

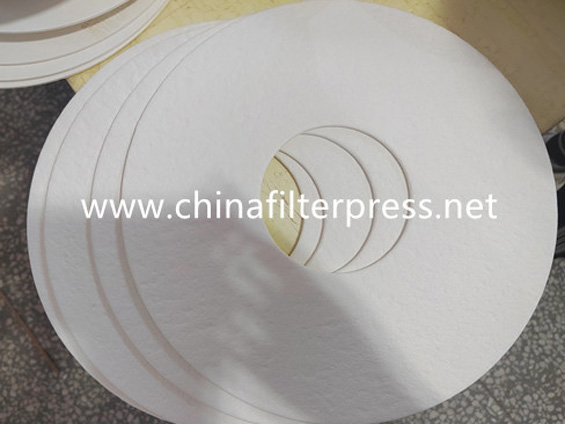

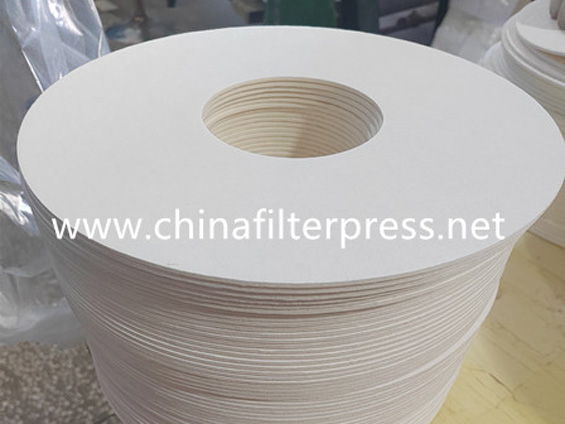

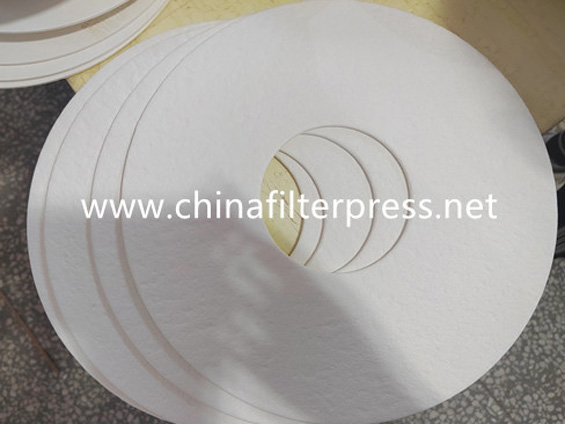

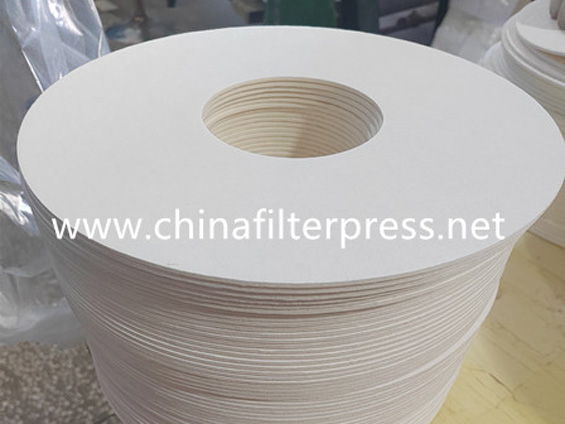

Horizontal Plate Filter Paper: Horizontal plate filter paper is often used in industrial processing. Filter paper is usually designed to meet the manufacturer's specifications. The absolute micron retention range is 1-100 microns, but diatomaceous earth is often used with filter paper to obtain submicron filtration.

Oil filter paper: Filters engine oil to remove impurities. Oil filtration is usually performed by volume filtration. Lubricating oil filter paper is impregnated to resist high temperatures.

Laboratory filter paper: Laboratory filter paper can generally be divided into qualitative and quantitative types. In analytical chemistry applications, when inorganic compounds are filtered to separate the precipitate, the residue collected on the filter paper can be used to calculate the loss rate during the experiment.