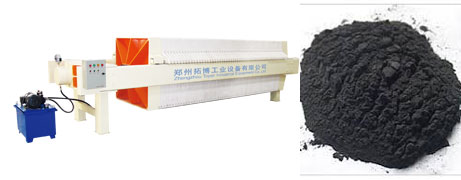

Graphite filter press

Graphite introduction

Graphite is a the carbonaceous elements crystalline minerals, its crystalline grid is a hexagonal layered structure. Electrically conductive, with a single quality of the diamond, carbon 60, carbon nanotubes are carbon elements, each other allotropes. Graphite in the industrial use of very wide, for high temperature on the production of smelting crucible, the lubricant of the machinery industry, the production of electrodes and pencil lead; widely used in the advanced refractory coating of the metallurgical industry, military industrial explosives and stabilizers, light industry of pencil lead, carbon brushes of the electrical industry, electrode in battery industry, fertilizer industry catalyst. The flake graphite after processing, but also produce colloidal graphite, graphite sealing materials and composite materials, graphite products, graphite friction reducing additives and other high-tech products, to become an important non-metallic mineral raw materials for various industrial sectorsProcess of Manufacturing :

Finely divided Graphite and clay (lime free stoneware clay) are wet grinded in a ball mill to get a required fineness of the mix. After grinding, the sludge passes to filter press. Excess water is removed by hydraulic dewatering press, then the plastic mass is compressed gradually by the extruder at an extrusion pressure 800 to 2000 PSI and finally it is forced through die of the diameter of the finished lead into a continuous string. The die head is mounted on a toggle joint so that the string is coiled as it comes out of the die and is caught in a shallow metal dish or on a carrying board. The lead is uncoiled by hand and pinched off into lengths each equal to 60mm length. The extruded leads are laid between boards and allowed to air dry. The dried leads are arranged in bundles in Graphite boxes for firing in a kiln at a temperature of 80-100ºC at a slow controlled rate of heating. The hot products are cooled out of contact with air. The cooled leads are immersed in boiling wax to remove grittiness and to increase strength and smoothness. The leads coming out from the boiling wax bath are packet 15 nos. in a rectangular plastic container 65 x 15 x 5mm. Twenty nos. of such plastic containers are packed together in a 3mm thick cardboard flexible container to facilitate distribution activities.Graphite filter press manufacturer

toper main production filter, filter variety, full specifications, superior quality, reasonable price and the company has strong technical force and perfect after-sales service of filter press, leading filter press technology, the production of filter press processing power, dehydration, high efficiency, long life, the country's most professional and trustworthy! Toper provide you with a variety of the graphite filter press has the most authoritative the graphite filter press price, the graphite filter press pictures repository, we will make every effort to provide you with accurate and comprehensive solutions.Request a quotation

Feedback Form

Contact E-Mail: toperkey@hi-toper.com