The New Pipe Filter Working Principle and Application

Pipe filter consists of takeover, cylinder, filter element and fasteners and other components mounted on the fluid materials pipeline fluid material can be removed in a large solid impurities, so that the machine can work equipment and instrumentation, reduce material clogging failure , stable process, ensure safety in production role.

Pipeline filters are widely used in the titanium dioxide production line, it has an important impact on the quality of the final chemical products — titanium dioxide. The company used a titanium dioxide filter pipeline operator labor intensity, fault frequent maintenance is difficult and costly, affecting the quality and yield of titanium dioxide production filtration fluid materials.

1. outsourcing pipe filter defect and analysis

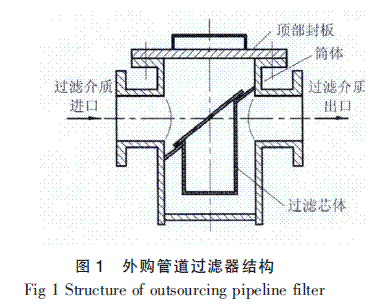

Purchased pipe filter structure shown in Figure 1.

Filter through to outsourcing pipeline failures for statistical analysis, we found that during the filtration process materials, purchased pipe filters exist three main use flaw:

1) feeding tube and a feeding tube at the same height, and the material in the filtration process flows were three times 90 ° turn. This design can not meet the production of titanium dioxide fluid-like material containing coarse impurities and quantity of material were flocculent debris and fluid viscosity characteristics, slow filtration rate, pressure drop filter, the filter is easy to damage, easy to make fine particles of titanium dioxide and filter out impurities in the filter residue is deposited in together, or through the filter element is deposited on the inner wall of the filter and an outlet pipe, causing the inner wall and the outlet pipes get clogged, affecting the yield and quality after filtration materials;

2) complex slagging and cleaning operations. Slagging and cleaning operations need to unscrew the top of the pipe filter seal plate screws in order to clean the filter impurities in the residue after removal filter, cleaning the filter put filters, pipe filters need to tighten the screw top closure plate, the entire slag and cleaning for a long time and labor intensive;

3) The overall use of ordinary stainless steel, lower than the average strength steel materials, especially filters and filter elements filter support means due to low intensity, it is difficult to bear the weight of the pipe material and the deposition of impurities weight of the residue, and the intolerant high temperature about 100 ℃ titanium dioxide filter material, so that the filter and the filter support means easy to crack deformation, maintenance is difficult, frequent maintenance and high maintenance costs. Titanium dioxide production process can not meet the high-temperature acid fluid materials.

2. The new pipeline filter Principles and Applications

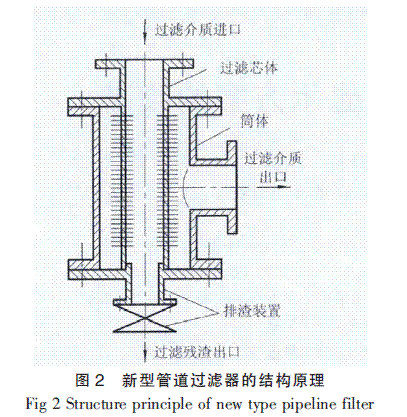

For outsourcing pipe filter defect, the company developed one kind of new pipe filters, including the filter element body, cylinder and slag filtration device, followed by the hex screw fastening from top to bottom. The new pipeline filter can theoretically reduce the original outsourcing pipeline slagging filter cleaning frequency and the frequency of repairs scrap, improve filtration efficiency, reduce labor intensity and reduce costs. Structure shown in Figure 2.

The new pipe filter characteristics:

1) The new pipe filter so that the material from the feed port to the discharge port of the entire filter channel flows only 1 90 ° steering structural design, to overcome the original outsourcing pipe filter feeding tube and a feeding tube at the same height, and the material in the filtration process flows were three times 90 ° steering defects, filtration rate increases, the filter pressure drop; reducing filter wear, avoid the fine titanium dioxide particles are deposited on the filter and filter in the inner wall and an outlet pipe blockage, improving filter After the material yield and quality.

Feed, the material principle is structured as follows: on terminating the feed tube, then opening side of the vertical 90 ° discharge tube, the lower end of the pipe filter residue outlet. A filter cartridge body by the flow according to the filter and filter media particle design has opened a round tubular filter core holes, two are on the end face of the flange and intermediate flange located round tubular core constitute the upper body, the body of the filter element flange end face through the feed tube and feeding tube flange connection. The upper end of the filter cartridge and the intermediate flange fastening. Filter cartridge comprises a cylinder and are located in a cylindrical first end connected to the flange 2, the second connection flange, the cylindrical sidewall having a central opening hole, the outlet opening at the connection between the flange and the cylinder by the pipe connection, first connecting flange filter cylinder and the filter body through the intermediate flange connected by Allen screws, filter outlet cylinder is connected via a discharge pipe flange flange and the discharge pipe.

2) slagging and cleaning operation more simple and easy to operate. The lower end of the residue outlet, and a residue outlet groove residue below. Slagging device includes an end for supporting and fixing the filter is too short tubular body, short on the tubular portion of the connector connected to the flange, located on the lower tubular took the short end of the connecting flange and a ball valve connecting flange and filter the lower end of the barrel by means of a second connection flange hexagon screw connection, in connection with the valve flange connection by hexagonal screws. The lower end of the same round tubular core inner diameter of the outer diameter of the tubular body and the filter element shorting the uppermost part of the uppermost portion of the tubular insert shorting in round tubular core body for supporting and fixing the filter element body. Residues below the valve is provided with a groove on the bottom of the flange connection is also provided with a filter holder.

Under new pipeline slagging filter cleaning operation outsourcing compared to the original pipe filter more simple, flexible, but also has the ability to backwash, can not dismantle, do not stop the pipe material transport situation slag discharge valve via the switch at any time slag, stop the pipeline transportation of materials but without the use of detachable pipe filters, reverse washing water from the tap outlet to achieve each member cleaning operations, reduce labor intensity, saving hours of operation, with a high superiority. And feed, filtration, slag channel linear design changes without labyrinth assembly, effective protection of pipe fittings equipment from wear and clogging, energy efficient.

3) selection of adaptation titanium dioxide production fiberglass and polypropylene. Filter cartridge and filter cartridge selection overall body made of glass fiber reinforced plastic material, or from polypropylene material welded into a whole. Slagging short tubular device and connection flange and a lower connecting flange is made of glass fiber reinforced plastic material made from polypropylene material integrally or welded into a whole, the whole ball is preferred fiberglass material purchased, you can use the material as a whole outer polypropylene purchase. High-temperature corrosion-resistant FRP, polypropylene and improve the pipe filter life, and fiberglass, polypropylene market price cheaper than stainless steel half, reducing manufacturing costs and maintenance costs.

3. Conclusion

The new pipe filters titanium dioxide production line put into use two years, compared to the original use of outsourcing pipeline filter with a more simple and flexible operation, significantly reducing energy-efficient, cost and the associated annual cost savings than the use of outsourcing pipeline filters less than two-thirds, while also improving the quality of products.