Aluminum ceramic foam filter Features

Aluminum ceramic foam filter Features

Aluminum melt inclusions of 80% based on the presence of flaky Al2O3, MgO, Al2MgO4 like. Inclusion formation and ingredients, lining and chute material, furnace gas composition, refining and casting technology and other related. The presence of a small amount of the fine inclusions can play a lower crystallinity degree of supercooling, promote nucleation.

But the intensity of excessive presence of inclusions would ingot or products, plastic, corrosion resistance, anodic oxidation and appearance adversely affect the quality . At the same time, the inclusion of parasitic gases (mainly hydrogen), will cause pinholes products, loose, cracks and other defects. Thus, cleaning is the key process of aluminum and aluminum smelting. As the national economy more and more demand for high-quality aluminum products, aluminum melt Impurity technology is increasingly subject to widespread attention to the aluminum industry.

1. Common filtering method for molten aluminum

Modern aluminum melt purification process, the filter is close to the end of the last one cast purification processes. Prior to this, after the furnace refining flux, standing way, the media and non-media adsorption, though already removed 60% to 80% of the inclusions and gas, but the melt still dispersed with more subtle (the grain diameter is generally <15μm) inclusions (including chute and intermediate production contract secondary raw inclusions). In order to obtain a high-performance aluminum products, we must make those fine inclusions gathering and adsorptive separation. Compared to other purification methods, filtration method because of its low energy consumption, easy operation, high cleaning efficiency, less secondary pollution, has become molten aluminum terminal purification treatment process of choice.

(1)Glass cloth and mesh filter mainly by mechanical separation of inclusions interception, simple structure, low cost, suitable for inclusion filter out large particles, but the inclusion of micro filtration little effect, coupled with low heat intensity filter, life is short, filter unstable, it can only be used once, it is mainly used for pre-filtering the melt.

(2)Deep bed filter (DBF), also known as particle packing filter, primarily to strengthen the layered alumina or silicon carbide ball ball according to a certain proportion of the accumulation of grain size composition, can be filtered 10μm above inclusions, which filter high efficiency filtration capacity, long service life, regeneration is good, but there are replacement of the high cost, short-circuit and vulnerable to disturbance and inclusion desorption phenomena, and filter ball diameter is too small can cause capillary resistance, it is suitable for DBF high performance, large capacity melt filtration.

(3)The ceramic particles bonded plate or tube filter (BPF) using 2 ~ 5 mm diameter alumina or silicon carbide particles and a special binder and sintered filter mainly by the gap between the particles tortuous conduct, which the advantages of high thermal strength, low surface energy, low initial pressure head, high filtration efficiency (especially <20μm inclusions), filtered volume, lower overall costs, can be washed and continued use 20 d or more. But the article is mainly dependent on imports, high prices ,suitable for large quantities of high-end aluminum products.

(4) Cellular (straight hole) type filters and similar to car exhaust filter , using die extrusion molding or after sintering mold formed directly, have high strength, filtration resistance, the melt flow rate is stable, easy to replace, costs low advantages, disadvantages because of mold limit, the larger the aperture, the hole wall adsorption filter mainly relies on inclusion, low filtration efficiency.

(5) Funnel cup seam filter and liquid flux filter due to the reason of cost , operation or filtration efficiency and other aspects, its use is very big constraint.

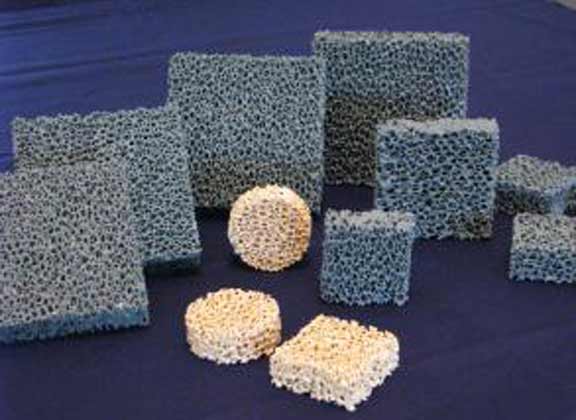

(6)Ceramic foam filter (CFF) is the most widely used filter in the area of aluminum melt filtration . The advantage is a high porosity, high filtration efficiency, easy to replace, low cost, adaptability, can also be isolated by filtration of solid inclusions portion of the liquid inclusions ; the disadvantage is the high temperature strength is low, short-lived (mostly single use) filtering small amount.