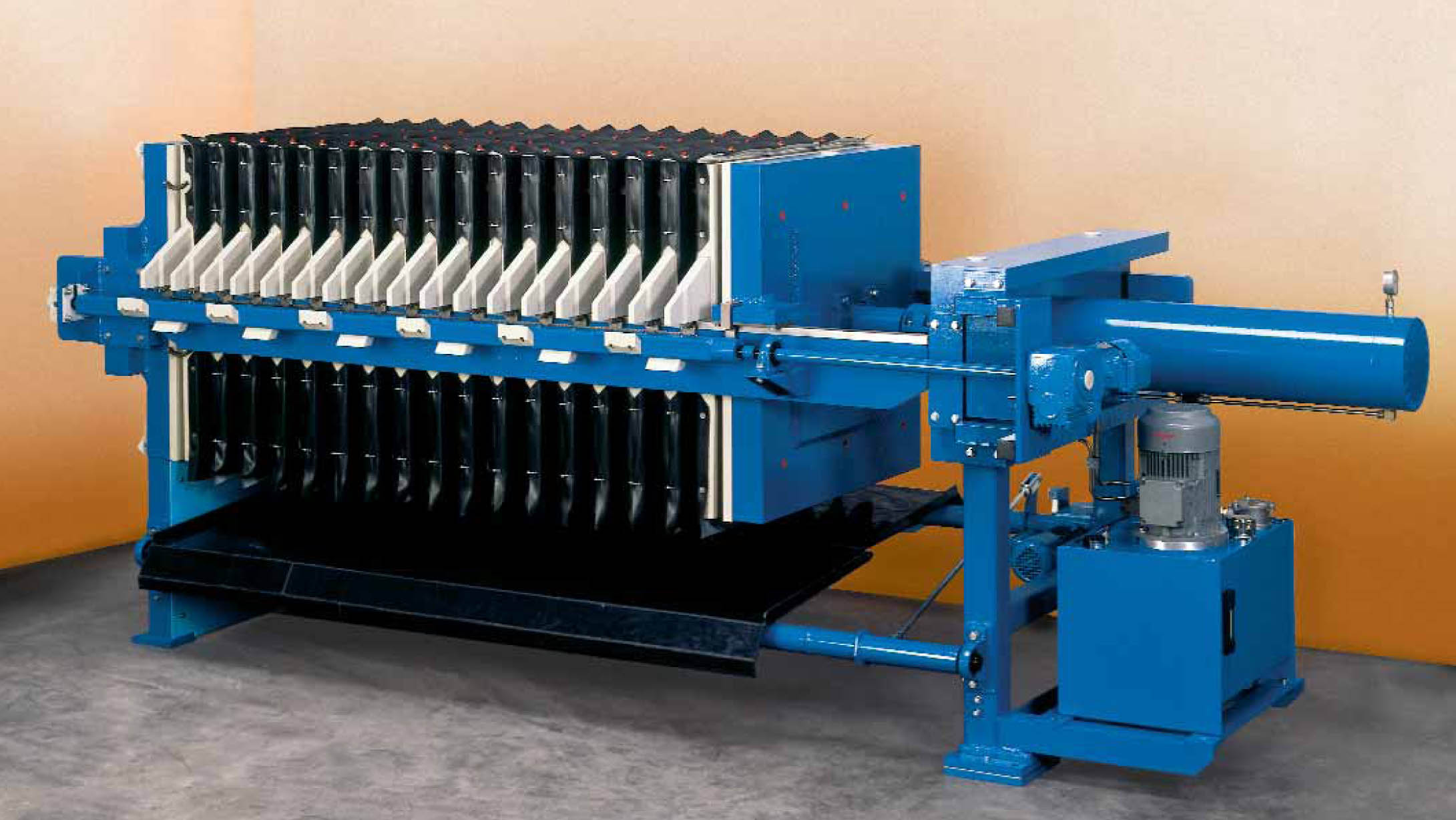

sludge filter presss

Sludge treament

Filtration is the most widely used method in the treatment of sludge produced by wastewater treatment. It can consist just in dreinage though sand beds or it can be mechanical under vacuum middle or high pressure conditions which require more sophisticated equipment. Filter presses operate applying very high pressures to the cake (from 5 to 15 bars and sometimes even more).sludge filter press performance

The filter press is suitable for almost all types of sludge: Hydrophilic organic sludge: inorganic conditioning is often recommended to enable satisfactory cake release due to minimal aderence to filter cloth. Hydrophilic inorganic sludge: the filer press generally requires the addition of lime only. Hydrophobic inorganic sludge: it is very dense and ideal for the filter press. It is dewatered without any preliminary conditioning. Oily sludge: the filter press can be used to treat sludge containing light oils, the presence of grease can sometimes impair the smooth running of the filter; clothes have to be degreased at frequent intervals.Some of the other features that make a Toper sludge filter press efficient and durable include:

1.Polypropylene plates that are rated to 100 psi 2.Semi automatic & automatic plate shifters 3.All-welded hydraulic cylinders 4.Air and electric hydraulic systems available 5.Polypropylene filter cloths with gaskets to prevent leaking We also carry a range of accessories that will make your new sludge filter even more efficient after it’s installed. For example, even though our dewatering systems make filter cakes that are 35-50% solids, a gas dryer can dewater your sludge even further. We also can elevate a wastewater filter press to allow for sludge discharge directly into a roll-off dumpster.Wastewater Sludge Filter Presses for Industrial Treatment Systems Installed Worldwide

An effective sludge filter press is an essential component of any wastewater treatment system. Without one, even the most thickened sludge from sedimentation systems, dissolved air flotation, and other treatment processes may have more water than what’s legally permissible. Fortunately, the cakes produced by a filter press can often go straight to the landfill, which leads to huge savings on disposal costs. When you’re looking to install an efficient sludge filter press in your facility, consider the Zhengzhou Toper Industrial Equipment Co. Ltd. Our filter presses are designed to be easily incorporated into any pre-existing wastewater system, and they will improve the treatment of your wastewater sludge immediately. We also make our presses easy for your staff to use by designing our equipment with the highest possible level of automation. This makes dewatering your sludge a simple process that requires minimal attention from your employees, allowing them to focus on more important tasks.Request a quotation

Feedback Form

Contact E-Mail: toperkey@hi-toper.com